AUDUBON'S Flatwire Edges

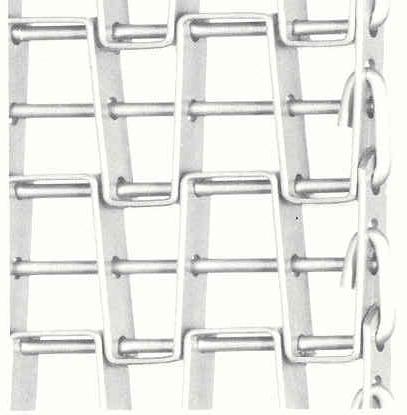

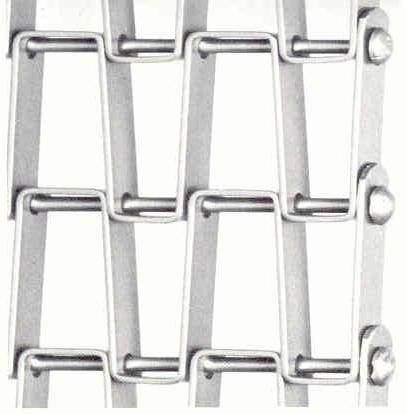

Welded Edge Clinched Edge.

FLATWIRE EDGE COMPARISONS

FLATWIRE BELT EDGES FOR STANDARD DUTY BELTS

CLINCHED EDGE

Strong edge that reduces chance of belt snagging or catching on conveyor protrusions.

Provided for better wear edge on misaligned conveyor systems.

Under heavier loads, assists in preventing belt from narrowing.

WELDED EDGE

Greater flexibility than the clinched edge.

Allows sprockets to be placed in the first opening of the belt.

Belt widths over 24" include an internal welds which reduces belt shrinkage under heavy loads without restricting flexibility of the belt.

FLATWIRE BELT EDGES FOR HEAVY DUTY BELTS

CLINCHED EDGE

Available in widths of 10" to 192".

Provided for better wear on the edge on misaligned conveyor systems

Under heavier loads, assists in preventing belt from narrowing.

Offers same flexibility as Welded Edge.

WELDED EDGE

Available in widths of 6" to 192"

Allows sprockets to be placed in the first opening on the belt.

Belt widths over 24" include an internal welds which provides greater strength, also reduces belt shrinkage under heavy loads

without restricting flexibility of the belt.

Internal welds can be supplied upon special request for belts under 24" wide.

AUDUBON Sales & Service

"Conveyor Belting Since 1884"

850 Pennsylvania Blvd

Feasterville, PA 19053

PH: (800) 523-0169 toll free in u.s.

PH: (215) 364-5451, FX: (215) 364-5538